1. Alxanka

Dhammaan noocyada iibiyeyaasha heerkulka ka hooseeya 3000 ℃ waxaa loo isticmaali karaa W brazing, iyo naxaas ama qalin ku salaysan alxanka waxaa loo isticmaali karaa qaybaha heerkulka ka hooseeya 400 ℃;Dahab ku salaysan, manganese ku salaysan, manganese ku salaysan, palladium ku salaysan ama biraha buuxinta ku salaysan ayaa inta badan loo isticmaalaa qaybaha loo isticmaalo inta u dhaxaysa 400 ℃ iyo 900 ℃;Qaybaha loo isticmaalo in ka badan 1000 ℃, biraha saafiga ah sida Nb, Ta, Ni, Pt, PD iyo Mo ayaa inta badan la isticmaalaa.Heerkulka shaqada ee qaybaha lagu xardhay alxanka saldhigga platinum ayaa gaadhay 2150 ℃.Haddii 1080 ℃ daawaynta faafinta la sameeyo ka dib naxaasta, heerkulka shaqada ugu badnaan wuxuu gaari karaa 3038 ℃.

Inta badan alxanka loo isticmaalo brazing w waxa loo isticmaali karaa naxaasta Mo, iyo naxaasta ama qalinka ku salaysan alxanka waxa loo isticmaali karaa qaybaha Mo ka shaqeeya 400 ℃;Qalabka elektaroonigga ah iyo qaybaha aan dhisnayn ee ka shaqeeya 400 ~ 650 ℃, Cu Ag, Au Ni, PD Ni ama Cu Ni alxan ayaa loo isticmaali karaa;Biraha ku salaysan Titanium ama biraha kale ee saafiga ah ee buuxinaya dhibco dhalaalid sare ah ayaa loo isticmaali karaa qaybaha ka shaqeeya heerkul sare.Waa in la ogaadaa in manganese-ku-saleysan, kobalt-ku-saleysan iyo biraha buuxinta nikkel-ku-saleysan guud ahaan laguma talinayo si looga fogaado abuuritaanka xeryahooda jajaban ee kala-goysyada brazing.

Marka qaybaha TA ama Nb loo isticmaalo ka hooseeya 1000 ℃, copper ku salaysan, manganese ku salaysan, cobalt ku salaysan, titanium ku salaysan, nikkel ku salaysan, dahab ku salaysan iyo palladium ku duro irbado ayaa la dooran karaa, oo ay ku jiraan Cu Au, Au Ni, PD Ni iyo Pt Au_ Ni iyo Alxannada Cu Sn waxay leeyihiin qoyn wanaagsan oo TA iyo Nb ah, tollayn wanaagsan oo samaysmaya iyo xoog wadajir ah oo sarreeya.Maaddaama biraha buuxinta qalinka ku salaysan ay u muuqdaan inay ka dhigaan biraha birta ah kuwo jajaban, waa in laga fogaadaa intii suurtogal ah.Qaybaha loo isticmaalo inta u dhaxaysa 1000 ℃ iyo 1300 ℃, biraha saafiga ah Ti, V, Zr ama Alloys ku salaysan biraha kuwaas oo ka samaysan adag aan xad lahayn iyo dareere iyaga la socda waa in loo xusho sida biraha buuxinta biraha.Marka heerkulka adeeggu sarreeyo, birta buuxinta ee ay ku jirto HF waa la dooran karaa.

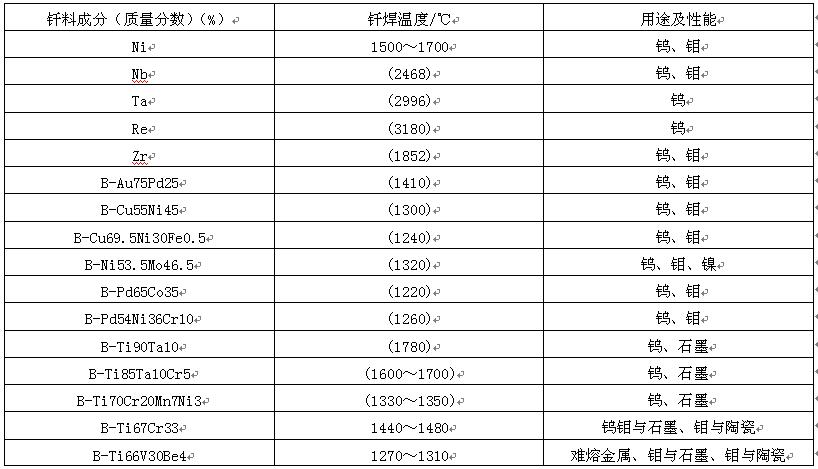

W. Fiiri shaxda 13 ee biraha buuxinta biraha ee Mo, Ta iyo Nb ee heerkul sare.

Shaxda 13 Biraha buuxinta brazing ee heerkulka sare ee biraha refractory

Kahor inta aan la jarin, waxaa loo baahan yahay in si taxadar leh looga saaro oksaydhka dusha sare ee birta celisa.Shiidi makaanikada, ciid qarxinta, nadiifinta ultrasonic ama nadiifinta kiimikada ayaa la isticmaali karaa.Nadiifinta waa in isla markiiba la sameeyaa ka dib habka nadiifinta.

Jilicsanaanta ku jirta W, qaybaha w waa in si taxadir leh loogu xalliyaa hawsha isku xidhka qaybaha si looga fogaado jebinta.Si looga hortago samaynta karbidhida tungsten ee jaban, xidhiidhka tooska ah ee u dhexeeya W iyo graphite waa in laga fogaadaa.Cadaadiska alxanka ka hor ama alxanka ka hor waa in la tirtiraa ka hor alxanka.W aad bay u fududahay in oksidize marka heerkulku kordho.Shahaadada faakuumku waa inay ahaataa mid aad u sareysa inta lagu jiro istaagga.Marka brazing lagu sameeyo gudaha heerkulka 1000 ~ 1400 ℃, heerka faakuumku waa inuusan ka yarayn 8 × 10-3Pa. daawaynta faafinta alxanka ka dib.Tusaale ahaan, alxanka b-ni68cr20si10fel waxa loo isticmaalaa in lagu xidho W at 1180 ℃.Ka dib saddex daawaynta faafinta ee 1070 ℃ / 4h, 1200 ℃ / 3.5h iyo 1300 ℃ / 2h alxanka ka dib, heerkulka adeegga ee wadajirka brazed wuxuu gaari karaa in ka badan 2200 ℃.

Isku-dhafka yar ee ballaadhinta kulaylka waa in la tixgeliyo marka la ururinayo isku-dhafka birta ah ee Mo, farqiga wadajirka ah waa inuu ahaadaa inta u dhaxaysa 0.05 ~ 0.13MM.Haddii qalab la isticmaalo, dooro shay leh isku-beeg yar oo balaadhinta kulaylka.Mo recrystallization waxay dhacdaa marka brazing ololka, foornada jawiga la xakameeyey, foornada faakuumka, foornada kicinta iyo kulaylka iska caabinta ay ka badato heerkulka dib ukrastallization ama heerkulka dib ukrastallization hoos u dhaco sababtoo ah faafinta walxaha alxanka.Sidaa darteed, marka heerkulku ku dhawaado heerkulka recrystallization, wakhtiga gaabintu waa ka sii fiicnaanaysaa.Marka aad ka sare marayso heerkulka recrystallization ee Mo, wakhtiga naxaasta iyo heerka qaboojinta waa in la xakameeyaa si looga fogaado dildilaaca ay keento qaboojinta degdega ah.Marka oxyacetylene flame brazing la isticmaalo, waxa fiican in la isticmaalo dareere isku dhafan, taas oo ah, borate warshadaha ama qulqulka brazing silver iyo socodka kulaylka sare leh oo ay ku jiraan fluoride calcium, kaas oo heli kara ilaalin wanaagsan.Habka ayaa ah in marka hore lagu dahaadho lakabka qulqulka birta lacagta ah ee dusha sare ee Mo, ka dibna la jaro qulqulka heerkulka sare.Dareeraha birta ah ee qalinku wuxuu leeyahay dhaqdhaqaaq heerkul hoose ah, heerkulka firfircoon ee qulqulka heerkulka sare wuxuu gaari karaa 1427 ℃.

Qaybaha TA ama Nb waxaa la doorbidayaa in lagu daboolo faakuum, iyo heerka faakuumku kama yarayn 1.33 × 10-2Pa.Haddii naxaas lagu sameeyo iyada oo la ilaalinayo gaaska aan shaqayn, wasakhda gaasta sida kaarboon monoxide, ammonia, nitrogen iyo carbon dioxide waa in si adag loo saaraa.Marka brazing ama caabbinta hawada lagu sameeyo, bir buuxinta gaarka ah iyo qulqulka habboon waa in la isticmaalaa.Si looga hortago TA ama Nb inay la xiriiraan ogsijiinta heerkulka sare, lakabka naxaasta birta ah ama nikkel ayaa lagu dhejin karaa dusha sare waxaana la samayn karaa daawaynta faafinta faafinta.

Waqtiga boostada: Jun-13-2022