Xakamaynta Heerkulka Sare ee Soosaarida iyo foornada qallafsan

Astaamaha

1. Labbiska heerkulka sare iyo waxtarka kulaylka

2. Xakamaynta heerkulka madax-bannaan ee aaga-badan, faaruqinta cadaadiska qayb ahaan shaqada

3. Jidhka ugu weyn wuxuu qaataa walxo heerkul sare leh, kaas oo ku qanacsan habka kuleylka kuleylka ee khafiifka ah iyo dhexdhexaadka ah iyo budada WC ee dhumuc weyn leh iyo walxo isku dhafan.

4. La qabso habka isku dhafka ah ee xakamaynta heerkulka.

5.Graphite gaashaanka kulaylka, walxaha kuleyliyaha graphite, 360-degree ku wareegsan kulaylka shucaaca.

6.Qaabka kala duwan ee dabinnada uumiga si loo yareeyo wasakhowga unugga

7.Nidaamka nadiifinta Nitrogen waxa uu leeyahay dahaar ka wanaagsan iyo hoos u dhigista.

8.Tiknooloojiyada dahaarka ee Patented si loo hubiyo isticmaalka muddada-dheer ee jirka kuleylka

9.Gubashada gaasta iyo nidaamka sifaynta ayaa la kulma heerka qiiqa

Tilmaamaha model caadiga ah iyo xuduudaha

| Qaabka | PJSJ-gr-30-1600 | PJSJ-gr-60-1600 | PJSJ-gr-100-1600 | PJSJ-gr-200-1600 | PJSJ-gr-450-1600 |

| Aagga Kulul ee Waxtarka leh LWH (mm) | 200*200*300 | 300*300*600 | 300*300*900 | 400*400*1200 | 500*500*1800 |

| Culayska Xamuulka (kg) | 100 | 200 | 400 | 600 | 10000 |

| Awood kuleyliyaha (kw) | 65 | 80 | 150 | 200 | 450 |

| Heerkulka ugu sarreeya (℃) | 1600 | ||||

| Saxnaanta xakamaynta heerkulka (℃) | ±1 | ||||

| Isku mid ahaanshaha heerkulka foornada (℃) | ±3 | ||||

| Shahaadada Vacuum Degree (Pa) | 4.0 * E -1 | ||||

| Heerarka bamgareynta (ilaa 5 pa)) | ≤10 daqiiqo | ||||

| Heerka sare u kaca cadaadiska (Pa/H) | ≤ 0.5 | ||||

| Qiyaasta daynta | 97.5% | ||||

| Habka wax u kala saarida | N2 cadaadis xun, H2 jawiga | ||||

| Gaaska gelinta | N2, H2, Ar | ||||

| Habka qaboojinta | qaboojinta gaaska aan shaqayn | ||||

| Habka sintering | Vacuum sintering, cadaadis qayb sintering, cadaadis aan cadaadis lahayn | ||||

| Qaab dhismeedka foornada | Horizontal, hal qol | ||||

| Habka furitaanka albaabka foornada | Nooca hinge | ||||

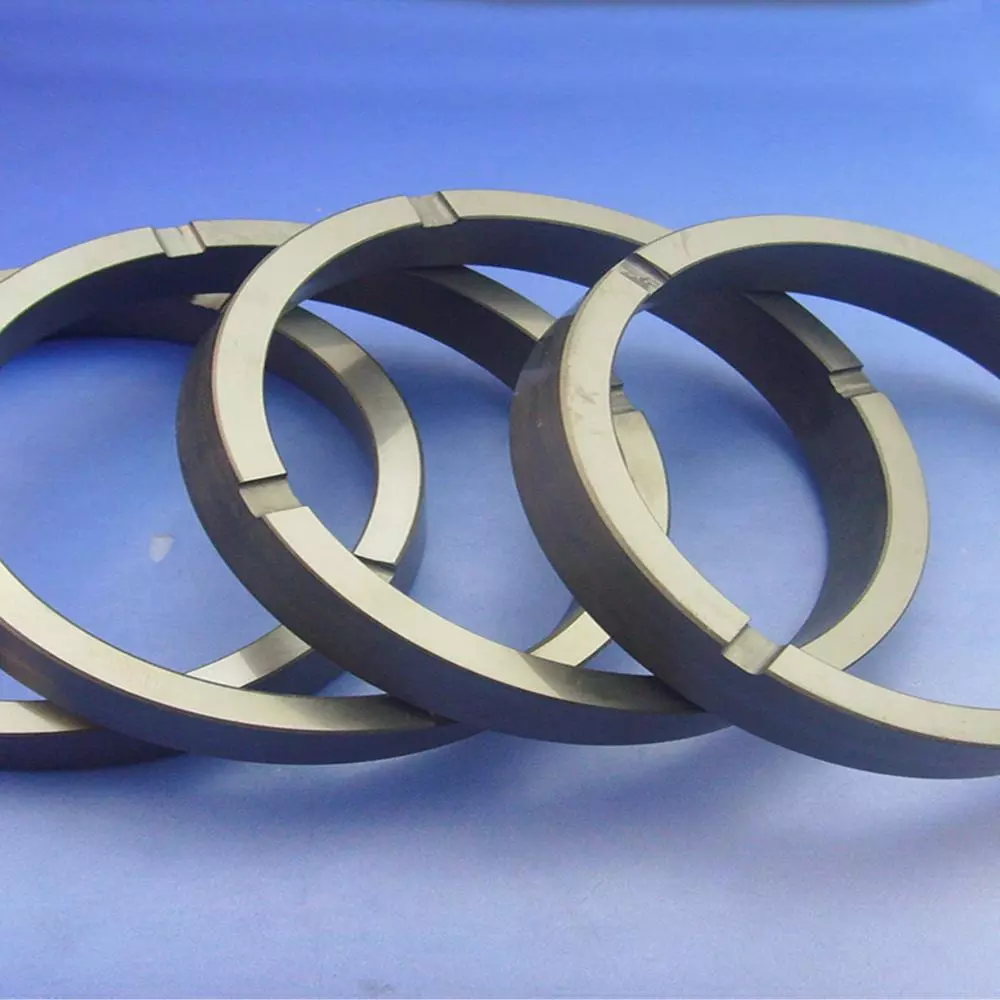

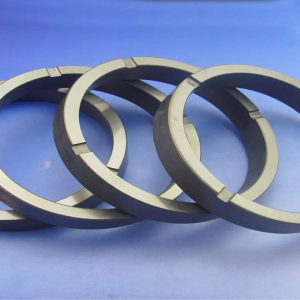

| Walxaha kululaynta | Walxaha kululaynta garaafka | ||||

| Qolka kululaynta | Qaab dhismeedka Graphit dareemeen adag oo jilicsan | ||||

| Thermocouple | Nooca C | ||||

| PLC & walxaha korontada | Siemens | ||||

| Xakamaynta heerkulka | EUROTHERM | ||||

| vacuum bamka | Bamka makaanikada iyo bamka xididdada | ||||

Kala duwanaanshaha ikhtiyaariga ah ee la habeeyey

| Heerkulka ugu badan | 1300-2800 ℃ | ||||

| Heerka heerkulka ugu sarreeya | 6.7 * E -3 Pa | ||||

| Qaab dhismeedka foornada | Horizontal,Vertical, hal qol | ||||

| Habka furitaanka albaabka | Nooca hinge, Nooca qaadista, Nooca fidsan | ||||

| Walxaha kululaynta | Walxaha kuleyliyaha garaafka, Walxaha kululaynta Mo | ||||

| Qolka kululaynta | Graphit ka kooban ayaa dareemay, Dhammaan muraayadaha birta ah ee milicsanaya | ||||

| Bambooyin nadiif ah | Bamka makaanikada iyo bamka xididdada; Makaanikada, xididdada iyo bambooyin faafinta | ||||

| PLC & walxaha korontada | Siemens, Omron, Mitsubishi, Siemens | ||||

| Xakamaynta heerkulka | EUROTHERM;SHIMADEN | ||||