Faakium kala-saarista iyo foornada qallafsan (Furnace MIM, foornada macdanta budada ah)

Astaamaha

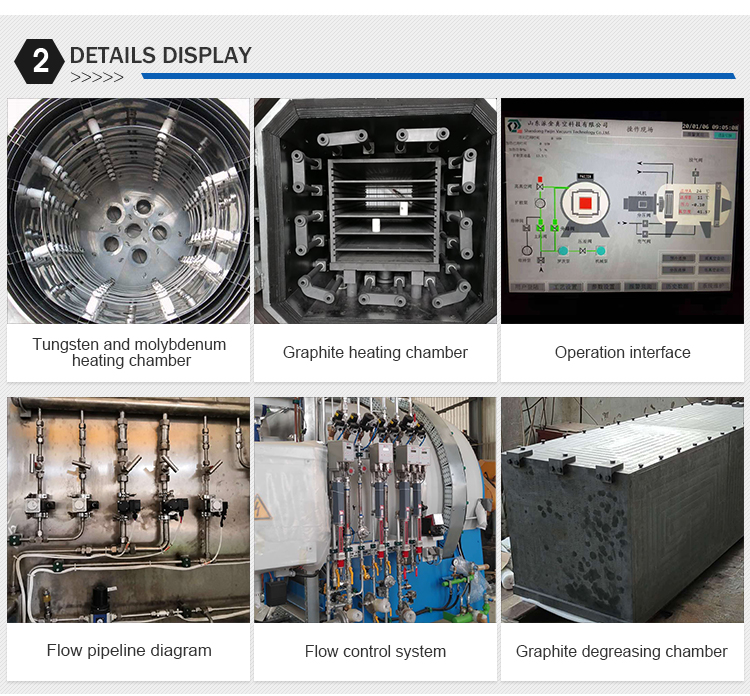

1. Shaashadda dahaarka graphite / shaashadda birta ikhtiyaari ah, walxaha kuleyliyaha 360 darajo ku wareegsan kuleylka shucaaca, naqshadaynta la isku halleyn karo.

2. Labbiska heerkulka sare iyo waxtarka kulaylka

3. Vacuum qayb ka mid ah cadaadiska / shaqada xakamaynta heerkulka aagga badan.

4. Qalab si otomaatig ah u buuxa, badbaado kaamil ah iyo nidaamka digniinta aan caadiga ahayn.

5. Xakamaynta habraaca saxda ah si loo gaadho tayada qaybeed ee joogtada ah loogana hortago wasakhaynta qaybaha iyo meelaha kulul.

6. Sanduuqa wasakhaynta ee daboolan iyo kondenseriyaha faakuumka si loo yareeyo wasakheynta qolka iyo unugga kuleylka.

7.Ka hortag wasakhowga qaybaha foornada. Sanduuqa hoos-u-dhaca labajibbaaran waxaa loo isticmaalaa in lagula tacaalo tiro badan oo wax lagu daro.

8. Waxay leedahay hawlaha soo saarista faakuumka dabacsan, vacuum sintering, sintering cadaadiska micro-positive iyo wixii la mid ah.

9. Qaabka ugu dambeeya ee kuleylka kuleylka iyo walxaha ayaa loo isticmaalaa, iska caabbinta cadaadiska waa mid xooggan, badbaadinta tamarta waa caddahay.

10.Waxay leedahay hawlaha heerkulka xad-dhaafka ah iyo qaylo-dhaanta cadaadiska, ilaalinta cadaadiska si toos ah mashiinka, si toos ahilaalinta cadaadiska xad dhaafka ah, isdhexgalka ficilka iyo wixii la mid ah, badbaadada qalabka sare.

11.Hawlgalka fog, ogaanshaha qaladka fog iyo hawlaha cusboonaysiinta software fog, iwm.

Tilmaamaha model caadiga ah iyo xuduudaha

| Qaabka | PJSJ-gr-30-1600 | PJSJ-gr-60-1600 | PJSJ-gr-100-1600 | PJSJ-gr-200-1600 | PJSJ-gr-450-1600 |

| Aagga kulul ee waxtarka leh LWH (mm) | 200*200* 300 | 300*300* 600 | 300*300* 900 | 400*400* 1200 | 500*500* 1800 |

| culeyska culeyska (kg) | 100 | 200 | 400 | 600 | 10000 |

| Awood kuleyliyaha (kw) | 65 | 80 | 150 | 200 | 450 |

| Heerkulka ugu sarreeya (℃) | 1600 | ||||

| Saxnaanta xakamaynta heerkulka (℃) | ±1 | ||||

| Isku mid ahaanshaha heerkulka foornada (℃) | ±3 | ||||

| Shahaadada vacuum ee shaqada (Pa) | 4.0 * E -1 | ||||

| Heerarka bamgareynta (ilaa 5 pac) | ≤10 daqiiqo | ||||

| Heerka sare u kaca cadaadiska (Pa/H) | ≤ 0.5 | ||||

| Qiyaasta daynta | 97.5% | ||||

| Habka wax u kala saarida | N2 cadaadis xun, H2 jawiga | ||||

| Gaaska gelinta | N2, H2, Ar | ||||

| Habka qaboojinta | qaboojinta gaaska aan shaqayn | ||||

| Habka sintering | Vacuum sintering, cadaadis qayb sintering, cadaadis aan cadaadis lahayn | ||||

| Qaab dhismeedka foornada | Horizontal, hal qol | ||||

| Habka furitaanka albaabka foornada | Nooca hinge | ||||

| Walxaha kululaynta | Walxaha kululaynta garaafka | ||||

| Qolka kululaynta | Qaab dhismeedka Graphit dareemeen adag oo jilicsan | ||||

| Thermocouple | Nooca C | ||||

| PLC & walxaha korontada | Siemens | ||||

| Xakamaynta heerkulka | EUROTHERM | ||||

| vacuum bamka | Bamka makaanikada iyo bamka xididdada | ||||

| Kala duwanaanshaha ikhtiyaariga ah ee la habeeyey | |||||

| Heerkulka ugu badan | 1300-2800 ℃ | ||||

| Heerka heerkulka ugu sarreeya | 6.7 * E -3 Pa | ||||

| Qaab dhismeedka foornada | Horizontal,Vertical, Qol kali ah | ||||

| Habka furitaanka albaabka | Nooca hinge, Nooca qaadista, Nooca fidsan | ||||

| Walxaha kululaynta | Walxaha kuleyliyaha garaafka, Walxaha kululaynta Mo | ||||

| Qolka kululaynta | Garaafyada ka kooban ayaa dareemay, Dhammaan muraayadda biraha ka tarjumaysa | ||||

| Bambooyin nadiif ah | Bamka makaanikada iyo bamka xididdada; Makaanikada, Xididdada iyo bambooyin faafinta | ||||

| PLC & walxaha korontada | Siemens; Cumar; Mitsubishi; Siemens | ||||

| Xakamaynta heerkulka | EUROTHERM;S HIMADEN | ||||