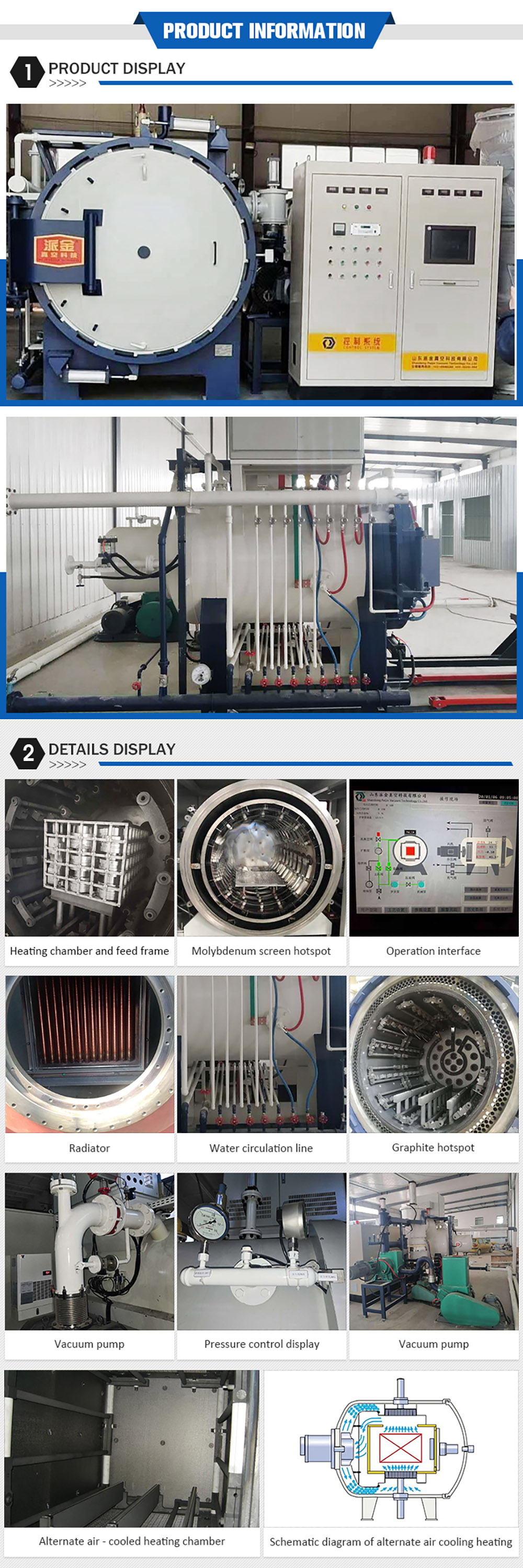

foornada gaaska deminta vacuum Horizontal oo leh hal qol

Waa maxay daminta gaaska faakuumka

Deminta gaaska Vacuum waa habka lagu kululeeyo qaybta shaqada ee faakuumka, ka dibna si deg deg ah loogu qaboojiyo gaaska qaboojinta cadaadiska sare iyo qulqulka sare, si loo hagaajiyo adkaanta dusha sare ee workpiece.

Marka la barbardhigo deminta gaaska caadiga ah, deminta saliidda iyo deminta qubeyska milixda, vacuum-gaaska cadaadiska sarreeya ee deminta wuxuu leeyahay faa'iidooyin muuqda: tayada dusha sare ee wanaagsan, ma laha oksaydhyo iyo carburization; Labbiska deminta wanaagsan iyo qallafsanaanta yar ee workpiece; Xakamaynta wanaagsan ee xoogga deminta iyo heerka qaboojinta la xakameyn karo; Wax soo saarka sare, badbaadinta shaqada nadiifinta ka dib deminta; Ma jiro wasakh deegaan.

Waxaa jira waxyaabo badan oo ku habboon deminta gaaska cadaadiska sarreeya ee faakuumka, oo ay ka mid yihiin: birta xawaaraha sare leh (sida qalabka wax lagu gooyo, caaryada birta, dhinta, cabbiraadaha, biraha matoorada jet), qalabka birta (qaybaha saacadaha, qalabka, mashiinnada), birta dhinta, birta sidata, iwm.

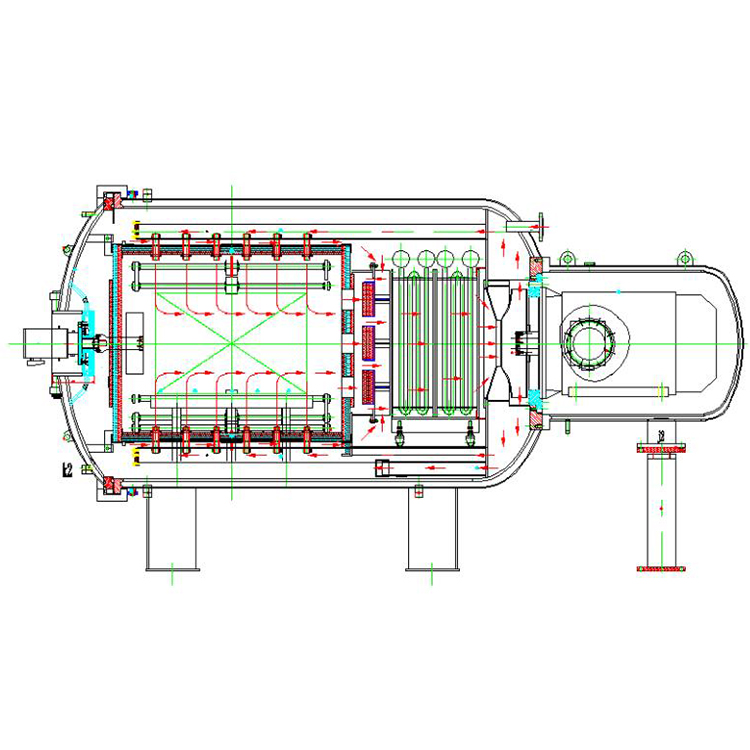

Paijin Vacuum gaaska quenching foornada waa foorno faaruq ah oo ka kooban jirka foornada, qolka kulaylka, marawaxadaha kululaynta kulul, nidaamka vacuum, nidaamka buuxinta gaaska, nidaamka cadaadiska qayb ahaan, nidaamka xakamaynta korantada, nidaamka qaboojinta biyaha, nidaamka deminta gaaska, nidaamka pneumatic, gawaarida quudinta foornada otomatiga ah iyo nidaamka sahayda tamarta.

Codsiga

Paijin Vacuum foornada deminta gaaskawaxay ku habboon tahay daweynta alaabta sida birta dhinta, birta xawaaraha sare leh, birta aan lahayn, iwm; daaweynta xalalka alaabta sida birta ah, titanium iyo titanium alloy; daawaynta nuugista iyo daawaynta xamaasadda ee agabka magnetic kala duwan; waxaana loo isticmaali karaa vacuum brazing iyo vacuum sintering.

Astaamaha

1. Xawaaraha qaboojinta sare:iyadoo la isticmaalayo wax ku oolnimada sare beddelka kulaylka labajibbaaran, heerka qaboojinta ayaa kordhay 80%.

2. Labbiska qaboojinta wanaagsan:Neefsashada hawada ayaa si siman oo jaranjaro loo dhigay agagaarka qolka kulaylka.

3. Keydinta Tamarta Sare:Neefsashada hawadu waxay si toos ah u xidhmi doontaa habka kuleylka, waxayna ka dhigaysaa kharashkeeda 40% ka yar.

4. Isku mid ahaanshaha heerkulka ka wanaagsan:Culayskeeda kuleyliyaha ayaa si siman loo dhigay agagaarka qolka kulaylka.

5. Ku haboon jawiga geedi socodka kala duwan:Lakabka dahaarka ee qolkiisa kuleyliyaha waxaa lagu sameeyaa lakab adag oo adag oo isku dhafan ama muraayad bir ah, oo ku habboon deegaanno kala duwan.

6. Xariif ah oo u fudud hab-socodka barnaamijka, ficil farsamaysan oo deggan oo la isku halayn karo, si toos ah, badh-si toos ah ama gacanta digniinta iyo muujinta cilladaha.

7. Badbaadinta inta jeer ee la xakameeyo marawaxada deminta gaaska, kulaylinta hawada convection optional, 9 dhibcood sahanka heerkulka ikhtiyaarka ah, daminta cadaadiska qayb ahaan iyo deminta isothermal.

8. Iyada oo leh nidaamka xakamaynta AI oo dhan iyo nidaamka hawlgalka gacanta ee dheeraadka ah.

Tilmaamaha model caadiga ah iyo xuduudaha

| Tilmaamaha model caadiga ah iyo xuduudaha | |||||

| Qaabka | PJ-Q557 | PJ-Q669 | PJ-Q7711 | PJ-Q8812 | PJ-Q9916 |

| Aagga Kulul ee Waxtarka leh LWH (mm) | 500*500 * 700 | 600*600 * 900 | 700*700 * 1100 | 800*800 * 1200 | 900*900 * 1600 |

| Culayska Xamuulka (kg) | 300 | 500 | 800 | 1200 | 2000 |

| Heerkulka ugu sarreeya (℃) | 1350 | ||||

| Saxnaanta xakamaynta heerkulka (℃) | ±1 | ||||

| Isku mid ahaanshaha heerkulka foornada (℃) | ±5 | ||||

| Darajada Vacuum ee ugu badan | 4.0 * E -1 | ||||

| Heerka sare u kaca cadaadiska (Pa/H) | ≤ 0.5 | ||||

| Cadaadis deminta gaaska (Bar) | 10 | ||||

| Qaab dhismeedka foornada | Horizontal, hal qol | ||||

| Habka furitaanka albaabka foornada | Nooca hinge | ||||

| Walxaha kululaynta | Walxaha kululaynta garaafka | ||||

| Qolka kululaynta | Qaab dhismeedka Graphit dareemeen adag oo jilicsan | ||||

| Nooca socodka gaaska demiya | Socodka beddelka toosan | ||||

| PLC & walxaha korontada | Siemens | ||||

| Xakamaynta heerkulka | EUROTHERM | ||||

| vacuum bamka | Bamka makaanikada iyo bamka xididdada | ||||

| Kala duwanaanshaha ikhtiyaariga ah ee la habeeyey | |||||

| Heerkulka ugu sarreeya | 600-2800 ℃ | ||||

| Heerka heerkulka ugu sarreeya | 6.7 * E -3 Pa | ||||

| Cadaadiska deminta gaaska | 6-20 Bar | ||||

| Qaab dhismeedka foornada | Horizontal,Vertical, hal aqal ama qolal badan | ||||

| Habka furitaanka albaabka | Nooca hinge, Nooca qaadista, Nooca fidsan | ||||

| Walxaha kululaynta | Walxaha kuleyliyaha garaafka, Walxaha kululaynta Mo | ||||

| Qolka kululaynta | Graphite ka kooban ayaa dareemay, Dhammaan muraayadaha biraha ah ee milicsanaya | ||||

| Nooca socodka gaaska demiya | Socodka gaaska beddelka ah ee tooska ah; Socodka gaaska beddelka tooska ah | ||||

| Bambooyin nadiif ah | Bamka makaanikada iyo bamka xididdada; Makaanikada, xididdada iyo bambooyin faafinta | ||||

| PLC & walxaha korontada | Siemens, Omron, Mitsubishi, Siemens | ||||

| Xakamaynta heerkulka | EUROTHERM;SHIMADEN | ||||

Xakamaynta tayada

Tayadu waa ruuxa alaabta, waa qodobka ugu muhiimsan go'aaminta warshad's mustaqbalka.Paijin qaadan tayada sida arrimaha mudnaanta ugu badan ee shaqo maalmeedkeena.Si loo hubiyo tayada wanaagsan ee alaabta our, waxaan bixinay dareen badan oo ku saabsan 3 dhinacyada.

1. Tan ugu muhiimsan: Aadanaha. Aadamuhu waa qodobka ugu muhiimsan shaqo kasta. Waxaan leenahay koorasyo tababar oo dhamaystiran shaqaale kasta oo cusub, waxaanan leenahay nidaamka qiimeynta si aan u qiimeyno shaqaale kasta heer (yar, dhexe, sare), shaqaale heerar kala duwan ayaa loo magacaabay shaqooyin kala duwan oo leh mushahar kala duwan. Nidaamkan qiimaynta, waxa'Ma aha oo kaliya xirfadaha, laakiin sidoo kale waxay qiimeeyaan mas'uuliyadda iyo heerka qaladka, awoodda fulinta iwm. Sidan oo kale, shaqaalaha warshadeena waxay diyaar u yihiin inay sameeyaan sida ugu fiican ee shaqadiisa. Oo si adag u raacda xeerarka maamulka tayada.

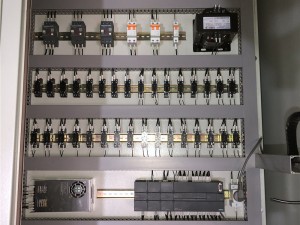

2. Qalabka ugu fiican iyo qaybaha: Waxaan kaliya ka iibsanaa alaabta ugu fiican ee suuqa, waxaan ognahay in kaydinta 1 dollar ee alaabta ay ku kici doonto 1000 dollars dhamaadka. Qaybaha muhiimka ah sida qaybaha korantada iyo bambooyinku waa dhammaan alaabooyinka astaanta ah sida Siemens, Omron,Eurotherm, Schneider iwm. Qaybaha kale ee lagu sameeyay Shiinaha, waxaanu dooranaa warshadda ugu fiican ee warshadaha iyo qandaraaska tayada alaabada ee la saxeexay iyaga, si loo hubiyo qayb kasta oo qayb kasta oo aan u isticmaalno foornada waa alaabta tayada ugu fiican.

3. Maaraynta Tayada Adag: Waxa aanu haynaa 8 goobood oo lagu hubinayo tayada foornada, Imtixaan kasta oo ka mid ah jeegaga waxa qaadaya 2 shaqaale ah, waxaana masuul ka ah 1 maareeye warshadeed. Meelahan hubinta, alaabta iyo qaybaha, iyo dhinac kasta oo foornada ah ayaa laba jeer la hubiyaa si loo hubiyo tayada. Ugu dambeyntii, ka hor intaan foornada ka bixin warshadda, waa in ugu dambeyntii lagu hubiyaa tijaabooyinka daaweynta kulaylka.